We create the Future of Plastic

We create the future of plastic. Instead of seeing it solely as a problem, we have recognized its potential for positive change. Viewed holistically, plastics often have a better eco-balance than other materials. We are therefore advocating a new approach to the production and recycling of plastics. Together, as conscious consumers, responsible businesses, and global citizens, we can rewrite the history of plastic.

Circling back – waste as a valuable resource

Helping to implement a circular economy for plastics

YUNUS SOCIAL BUSINESS X MELITTA GROUP

vishuddh — fair recycled plastic

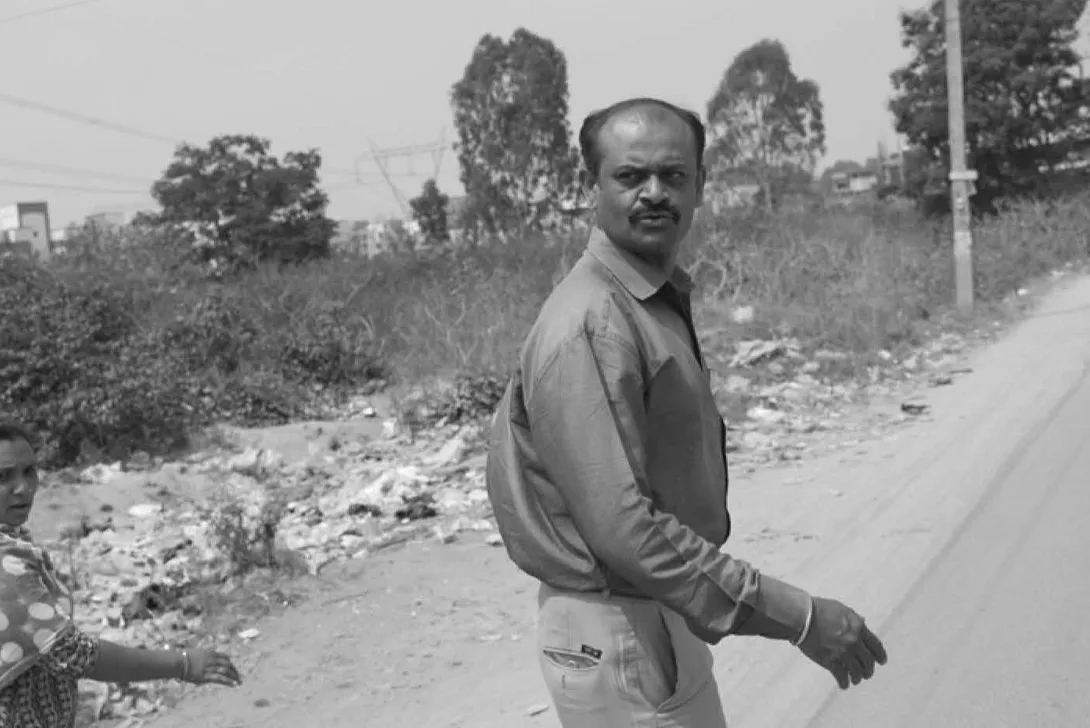

In partnership with the organization of Nobel Prize winner Muhammad Yunus – Yunus Social Business – we founded the recycling company Vishuddh Recycle in the southern Indian city of Bangalore. The company is expected to recycle up to 2,000 tons of plastic waste per year, with the resulting recyclate being used in our bin liner product segment. All profits generated by Vishuddh Recycle are reinvested or donated to charitable organizations.

“It is possible to create a company that serves the poor and where profit is a by-product, not the goal.” – Prof. Muhammad Yunus – Nobel Peace Prize winner and founder of Yunus Social Business GmbH

» I can give protective equipment to my employees. Because I can afford it now. «

Free healthcare makes life much easier and better for the waste pickers.

» We currently spend a lot of time and energy not only separating plastic, but also educating our suppliers about the separation of plastics in order to return them to the circular economy. «

» People used to dump their rubbish everywhere – today there are rubbish trucks and the waste is separated. «

Building empowerment to transform society.

» Thanks to my work, I can send my children to school and even save money for a house. «

» I want my children to have a better life. Thanks to my work, they will be able to study one day. «

» The biggest positive for me is our corporate culture, in which my talents were recognized and encouraged, and I was able to take on a more highly skilled role. «

» I always say: it’s not the plastic that’s the problem, but its reuse and recycling. «

» Today, I not only feel that I really belong to the organization I work for. I’m also part of a change that is leading to something good. «